What is a Quality Wheel

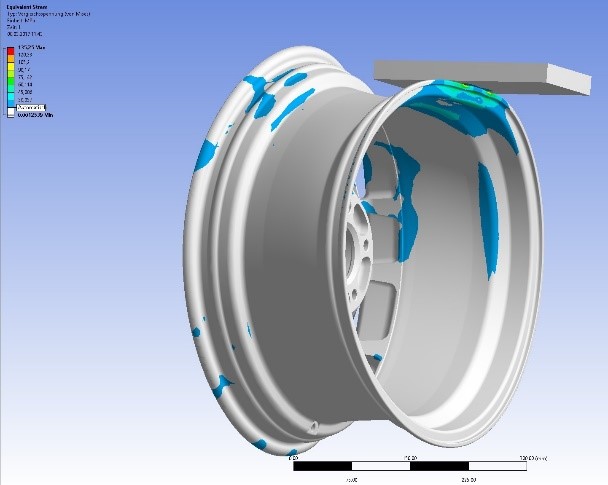

The quality of every Breyton wheel is our first priority. Even before physical testing at the test laboratory, we use FEM (finite element method) computer analyses to simulate all required wheel testing standards. In this way it is possible to predict a wheel’s characteristics and identify potential issues even before production begins. Final results are of course still determined by test benches in the laboratory. All Breyton wheels are designed and engineered to meet the German TÜV standards and are tested to German TÜV guidelines. Below we explain the standard tests all our wheels undergo..

The quality of every Breyton wheel is our first priority. Even before physical testing at the test laboratory, we use FEM (finite element method) computer analyses to simulate all required wheel testing standards. In this way it is possible to predict a wheel’s characteristics and identify potential issues even before production begins. Final results are of course still determined by test benches in the laboratory. All Breyton wheels are designed and engineered to meet the German TÜV standards and are tested to German TÜV guidelines. Below we explain the standard tests all our wheels undergo..

Rotating bending test

The rotational bending test simulates the lateral force, which impacts the wheel when negotiating a curve or bend.

The rotational bending test simulates the lateral force, which impacts the wheel when negotiating a curve or bend.

For this bending test, the wheel flange is rigidly clamped to a test bench with a clamping ring on the inner rim shoulder and stressed with a rotating bending moment at the wheels mounting surface. This test is by far the most important one when it comes to product safety of our aluminum wheels.

Endurance wheel test

Using this test, we are able to simulate the normal and lateral forces that exert on the wheel and tire when running on the road. We always run beyond the standard requirement to ensure the safety and security of our products.

Impact test

This test simulates a lateral impact, for example when driving up to a curb. The outer rim shoulder of the wheel with tire is hit with a specified drop weight. No sudden loss of air may occur during this test.

Corrosion test on paint finishing

The corrosion test is performed using salt spray or salt fog, for example in a so-called CASS test chamber. In this chamber, a salt water solution with added acetic acid and copper chloride is used, to provide a highly corrosive environment specific to the materials and surface coatings.

The corrosion test is performed using salt spray or salt fog, for example in a so-called CASS test chamber. In this chamber, a salt water solution with added acetic acid and copper chloride is used, to provide a highly corrosive environment specific to the materials and surface coatings.

Our products usually are subjected to such an environment for 240 hours to simulate deterioration caused by outdoor weather conditions.

Certification

TÜV certification of a company, as well as its products, is one of the most highly respected certifications guaranteeing quality and safety for the consumer.

TÜV certification of a company, as well as its products, is one of the most highly respected certifications guaranteeing quality and safety for the consumer.

Each Breyton wheel is designed and engineered to meet the German TÜV standards set by the German transportation authority.

Additionally, we as a company have a certified quality management system and certified processes for ensuring production conformity.

In conjunction with that, our production facilities themselves are certified with DIN ISO 9001 certification for effective quality management, and the international quality standard of the automobile industry, ISO TS 16949.