What essentially drives our engineers in the Breyton Design Lab is our sense of craft and aesthetic. Our sense of the very perfection of a wheel. Fair enough, it needs to be round and applicable to a car, you say? To us it is more. To us it is the essence of our creativity and the base of our thoughts. The look and the feel and the driving characteristics is what we strive to perfect and what we will never quite achieve to perfect.

CONCEPT

A Perfect product is not a result of luck or chance, a perfect product is formed by a perfect procedure. From the start of the initial drawing on paper following through to the finishing after wheel production constant quality control and management are top priority not only in our actions but also in our thinking. We always work on extending the limits of the physical processes behind design and manufacturing of our performance wheels.

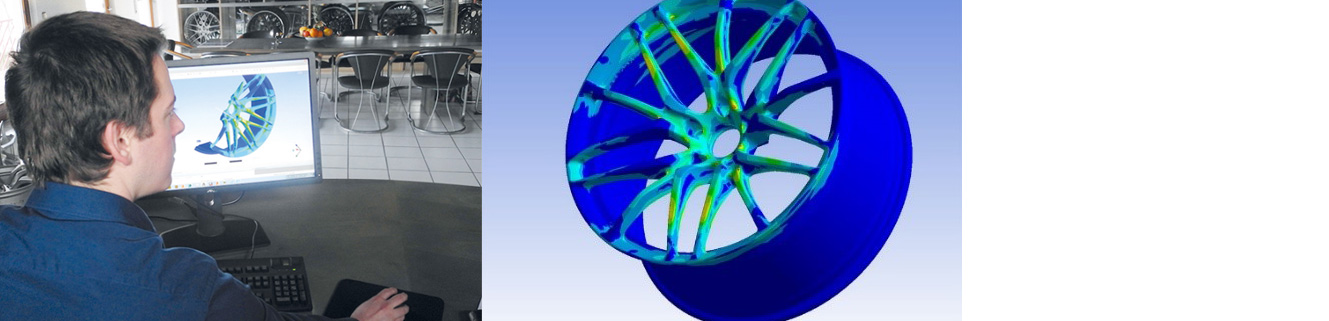

DEVELOPMENT

From the wheel concept on paper to the finished product., Breyton adopts modern computerised analysis and design systems that improve production standards and drastically reduce time-to-market.

Beside Classic CAD and CAM applications, a dedicated FEM (Finite Element Method) based software makes it possible to optimise geometric shape and choice of material, to identify the product's critical factors by a virtual simulation of a physical or mechanical problem. FEM analysis today allows for stunning design coupled with highest strength.